Turning Emissions into Assets, On-Site.

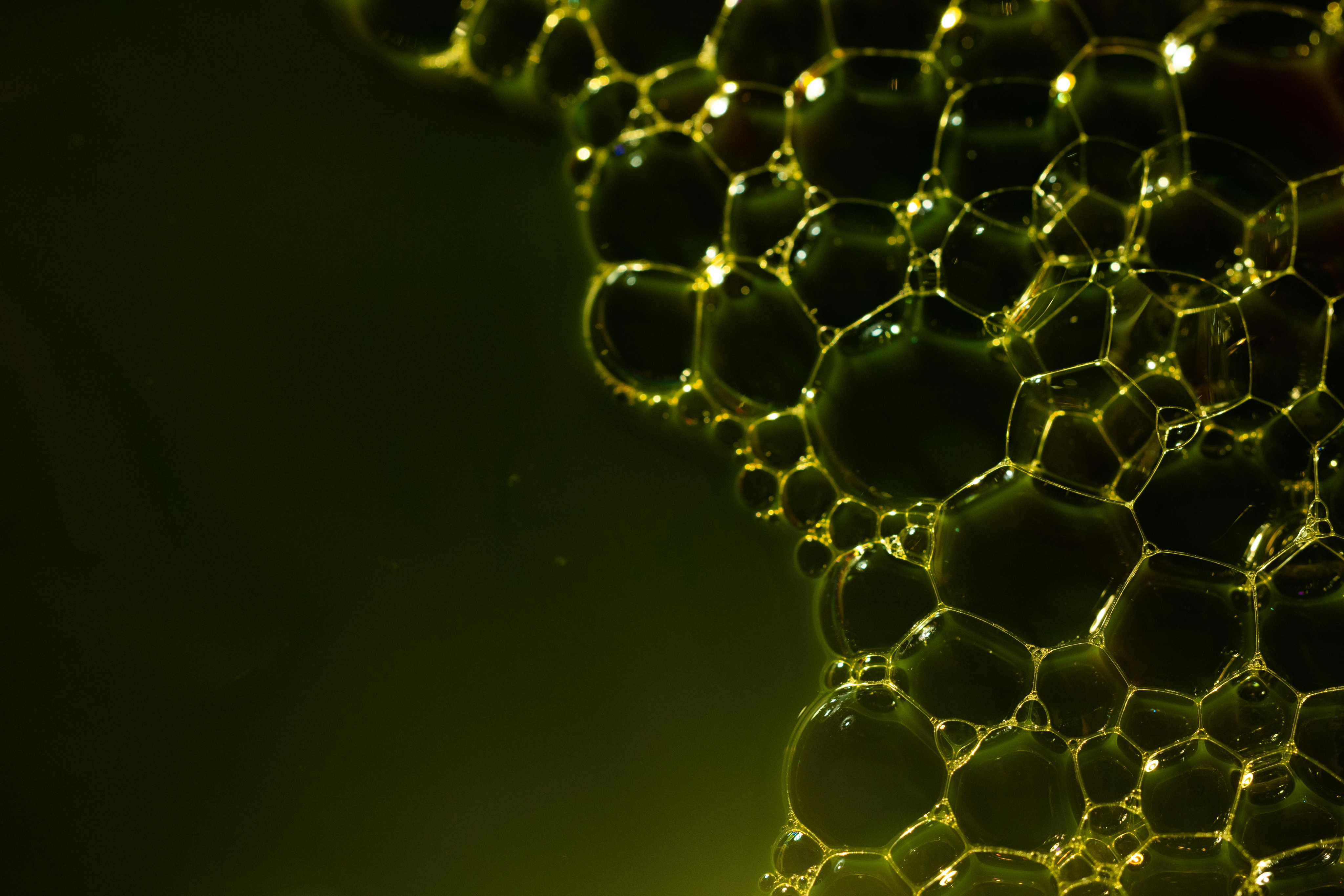

Blue2’s proprietary photobioreactors capture industrial CO₂ at the source and feed it to microalgae, transforming emissions into biosourced molecules for cosmetics, pharma, and specialty chemicals.

How it works

01 -

Capture

02 -

Cultivate

03 -

Extract

04 -

Valorize

Why it’s different

On-site & Modular Intensified Production

Container units scale with demand, minimal downtime. Low footprint, yet high molecule productivity.

Plug-and-Produce

Integrates with existing utilities; remote monitoring, automated controls.

Spec-Driven Molecules

We tune strains and conditions to target your ingredient profile.

Closed, Clean, Consistent

No open ponds; controlled light and gas flow for reliable quality

Predictive by Design

Multiphysics + data models guide strain selection and production planning.

Circular from Day One

CO₂ becomes revenue-generating outputs, not just a cost center.

What our buyers get

Blue2 turns your CO2 into valuable exclusive ingredients that you can reuse into your own production.

01

Qualified strategic ingredients

ready for formulation (e.g., antioxidants, texturizers, bioactives)

02

Co-product streams

(proteins, biofertilizers) to boost economics and sustainability KPIs.

03

Data package

(run logs, LCA inputs, batch analytics) to support ESG reporting.

Discover the team behind